News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

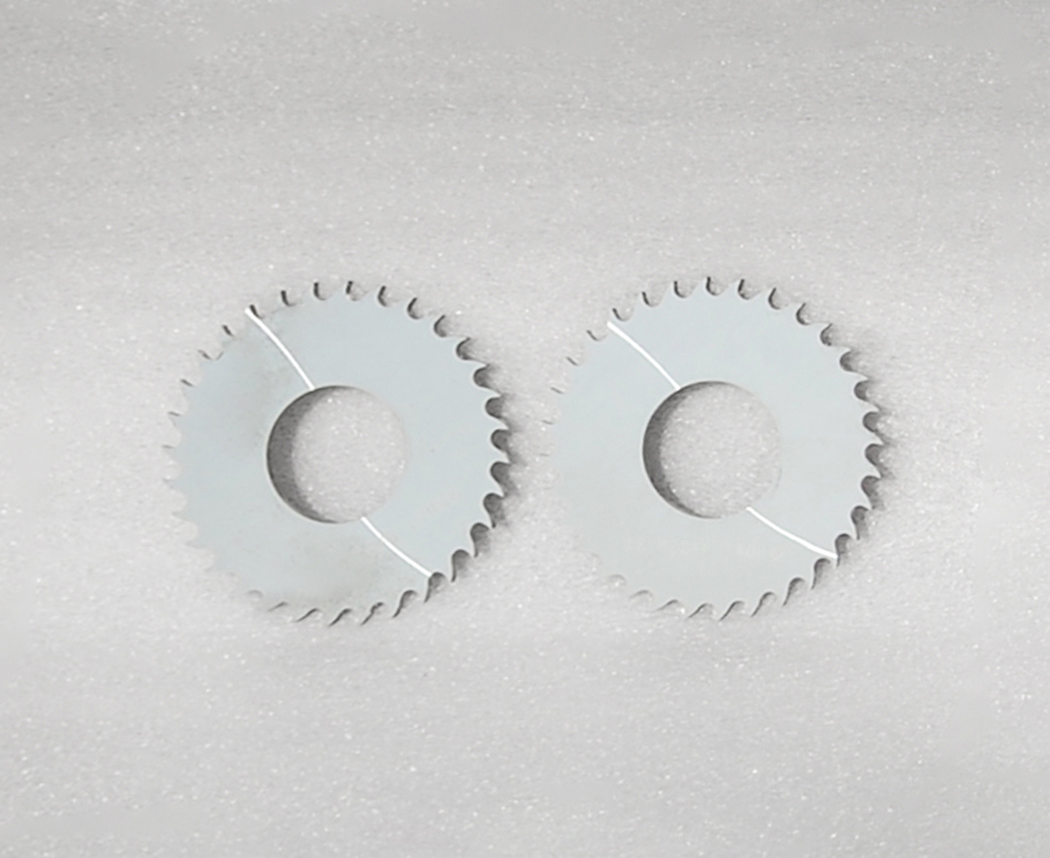

What are the characteristics of tungsten steel round fox teeth

Tungsten steel round fox teeth (usually referring to cutting tools or parts made of tungsten steel material with circular arc teeth, such as gears, milling cutters, saw blades, etc.) have the following characteristics, mainly derived from the material properties of tungsten steel (hard alloy) and the structural advantages of circular arc teeth:Sources:www.idvd.com.cn | PublishDate:2025.05.27

1、 Core advantages brought by material properties

1. High hardness and wear resistance

Tungsten steel (hard alloy) is sintered from metal binders such as tungsten carbide (WC) and cobalt (Co), with a hardness of HRA 85-93 (equivalent to HRC 68-82), much higher than high-speed steel and ordinary steel.

Application scenario: Suitable for processing high hardness materials (such as quenched steel, cast iron, high-temperature alloys) or wear-resistant parts that require long-term precision maintenance (such as gears, cutting tools), with a service life several times longer than ordinary steel.

2. High heat resistance (red hardness)

It can maintain hardness and cutting performance even in high temperature environments (up to 800-1000 ℃), and is not easily softened by frictional heat generation.

Application scenarios: Suitable for high-speed cutting, dry cutting, or long-term continuous machining, reducing tool wear and thermal deformation.

3. High strength and impact resistance

Although brittle compared to high-speed steel, tungsten steel can balance strength and impact resistance through a reasonable cobalt content ratio (such as higher cobalt content, better toughness).

Typical data: The bending strength can reach 1300-3000 MPa, suitable for working conditions that can withstand alternating loads (such as gear transmission and milling).

4. Corrosion resistance and chemical stability

Corrosion resistant to acid, alkali and other chemical media, suitable for working in humid or corrosive environments (such as wear-resistant components in chemical equipment and marine engineering).

2、 Structural advantages of circular tooth shape

1. Smooth meshing and low noise

The tooth surface of circular arc gears (such as circular arc gears and cycloidal gears) is a convex concave circular arc meshing, with long and continuous contact lines. Compared with involute gears, the impact and vibration during transmission are smaller, and the noise can be reduced by 10-20 dB.

Application scenarios: precision transmission equipment (such as robot reducers, aerospace gearboxes), and high noise requirements (such as medical devices, automotive gearboxes).

2. Strong load-bearing capacity and high transmission efficiency

The contact stress distribution of circular arc teeth is uniform, and the single tooth bearing capacity is 30% -50% higher than that of involute gears. Moreover, the sliding friction coefficient is low during meshing, and the transmission efficiency can reach over 98%.

Application scenarios: Heavy duty transmission systems (such as gearboxes for mining machinery and metallurgical equipment), high-power density equipment (such as wind power gearbox).

3. Good fault tolerance and insensitivity to installation errors

The tooth profile of circular arc teeth has low sensitivity to center distance error and axis parallelism error, allowing for a certain degree of installation deviation while maintaining good meshing and reducing assembly difficulty.

Application scenario: Large equipment with complex on-site installation conditions (such as construction machinery, heavy machine tools).

4. Excellent cutting performance (tool application)

The edge transition of circular arc tooth cutting tools (such as circular arc milling cutters and drill bits) is smooth, and the cutting force is evenly distributed during cutting, which can reduce the risk of edge cracking and is suitable for machining complex curved surfaces or high hardness materials.

Typical applications: Mold processing (such as the circular arc cavity of automotive cover mold), surface milling of aerospace structural components.

3、 Limitations and Precautions

1. High cost

Tungsten steel raw materials are expensive, and the processing of circular tooth shapes (such as grinding and wire cutting) requires specialized equipment, resulting in overall costs much higher than ordinary steel parts.

2. High brittleness

Although its toughness is better than ceramic cutting tools, it still needs to avoid severe impacts (such as emergency stop and overload), suitable for stable load conditions, and requires high-precision bearings and rigid support structures.

3. High processing difficulty

High precision circular arc teeth require CNC grinding or electrical discharge machining, which requires high equipment and process requirements, and low efficiency in small-scale production.

4、 Typical application areas

Mechanical manufacturing: high-precision reducer gears, machine tool spindle transmission gears, wear-resistant guide rail sliders.

Cutting tools: arc milling cutters, hard alloy drill bits, gear cutters.

Aerospace: Engine transmission gears, aircraft structural component machining tools.

Petrochemical industry: corrosion-resistant pump impellers, high-pressure valve seals.

Electronics and precision instruments: semiconductor equipment transmission components, optical lens processing tools.